Qualification of testing of Titanium Stress Joints - Galvanic Hydrogen Mitigation

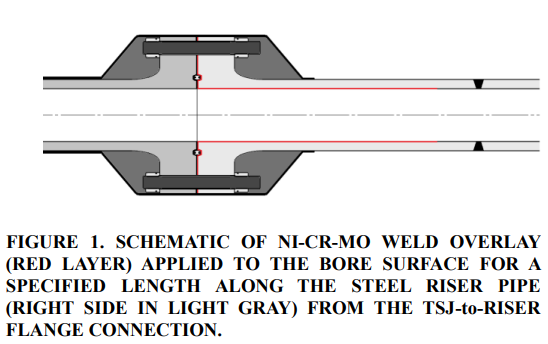

A three-phase laboratory test qualification program for Titanium Stress Joint (TSJ) use in an offshore steel catenary riser (SCR) system handling hot, marginally sour well brine fluid offers guidance for expanded, safe TSJ use in hot sour well service. Phase 1 results indicated a reasonable concern and risk for long-term excessive hydrogen uptake and damage to the TSJ when directly coupled with the steel riser and steel topside piping. An alternative TSJ design, incorporating an Alloy 625 cathode buffer transition between adjoining steel tubulars, was proposed for mitigation of galvanic hydrogen charging uptake and damage prevention for hot sour fluid service. This “Tri-Metal couple” design was modeled in Phase 2 using polarization curves as input, and simulations projected insignificant hydrogen charging on TSJ bore surfaces exposed to “Worst-Case Sour” brine fluid at 250°F (121°C). Phase 3 aimed at qualifying the TSJ welds for even more severe and acidic sour well fluid service conditions up to 275°F (135°C), via fatigue crack growth rate (FCGR)and J-R fracture toughness testing of weld metal, and S-N fatigue and slow strain rate (SSR) tensile testing of cross-welds. These tests confirmed the high degree of hot sour environmental resistance for Grade 29 Titanium welded joints, and reasonable compatibility with TSJ design requirements.

Tags

Fill out the form to access the full report.